|

Description

The throttle body is located on the intake manifold. Fuel does not enter the intake manifold through the throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

Operation

Filtered air from the air cleaner enters the intake manifold through the throttle body. The throttle body contains an air control passage controlled by an Idle Air Control (IAC) motor. The air control passage is used to supply air for idle conditions. A throttle valve (plate) is used to supply air for above idle conditions.

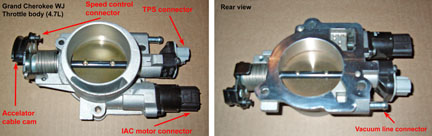

Certain sensors are attached to the throttle body. The accelerator pedal cable, speed control cable and transmission control cable (when equipped) are connected to the throttle body linkage arm.

A set screw is used to mechanically limit the position of the throttle body throttle plate. Never attempt to adjust the engine idle speed using this screw. All idle speed functions are controlled by the Powertrain Control Module (PCM).

Throttle body components, 4.7L engine

Cleaning

The throttle body can be cleaned one of two ways, either by simply spraying a throttle body cleaner into the throttle body while the engine is running, or for a more thorough job by removing the throttle body assembly and cleaning the parts manually.

Method 1: Cleaning without removal of the throttle body

Tools and parts needed:

- Safety glasses

- Carburetor / Throttle Body cleaner

- 10mm socket (resonator bolts)

- Flat blade screwdriver (hose clamp)

1. Operate the vehicle until operating temperature is reached.

2. Remove air cleaner duct clamp closest to resonator. Disconnect breather tube at resonator. Remove two bolts securing resonator to manifold and remove resonator by twisting up and away from throttle body.

3. With the engine at an idle, spray the entire contents of the combustion cleaner (Mopar P/N 04318001 recommended) directly into the throttle body. Allow the vehicle to load up with the cleaner to the point of almost stalling out.

4. Shut the engine OFF after the entire can is ingested.

5. With the hood closed and the vehicle parked inside the garage, allow the vehicle to soak for two to three hours. This will ensure that the engine will maintain its temperature and will allow proper solvent penetration.

6. Drive the vehicle on a highway/freeway that will allow the vehicle to be driven safely at the posted speed limit. Upon entering the highway/freeway, accelerate hard to the posted speed limit and maintain speed. Slow down and then perform 5 to 10 Wide Open Throttle (WOT) upshifts. Continue driving at the maximum speed limit for 1-2 miles (if conditions allow).

Method 2: Throttle body removal and manual cleaning process

Tools and parts needed:

- Safety glasses

- Shallow pan for cleaning (optional)

- Shop rags

- Carburetor / Throttle Body cleaner

- Toothbrush and/or Q-tips

- Flat blade screwdriver (hose clamp)

- 8mm socket (throttle body mounting bolts)

- 10mm socket (resonator bolts)

- T-20 Torx screwdriver (IAC motor bolts)

- Compressed air (optional)

- Gasket, 4.0L (T-body to manifold) P/N 53007543 MSRP: $2.25

- Gasket, 4.7L (T-body to manifold, usually not required as it is reusable) P/N 53030952AB MSRP: $7.45

4.0L removal

1. Remove air cleaner duct clamp closest to resonator. Disconnect

breather tube at resonator. Remove two bolts securing resonator to manifold and remove resonator by twisting up and away from throttle body.

2. Disconnect throttle body electrical connectors at MAP sensor, IAC motor and TPS.

3. Remove all control cables from throttle body (lever) arm.

4. Remove four throttle body mounting bolts.

5. Remove throttle body from intake manifold.

6. Discard old throttle body-to-intake manifold gasket.

4.7L removal

1. Remove air cleaner duct clamp closest to resonator. Disconnect

breather tube at resonator. Remove two bolts securing resonator to manifold and remove resonator by twisting up and away from throttle body..

2. Disconnect throttle body electrical connectors at IAC motor and TPS. The top connector has a release tab underneath, squeeze tab firmly upward to release. The release tab for the lower connector is facing toward the front of the vehicle.

3. Remove vacuum line at throttle body. This may require some slight back and forth twisting of the hose while pulling it out.

4. Remove all control cables from throttle body (lever) arm. Typically there are two, the throttle cable and speed control cable. To remove the throttle cable, rotate cam to slacken cable. The cable has a barrell-shaped end. The cable slides out sideways when aligned with the slot. The speed control cable is snapped onto its mounting stud, which it pulls away from. You can rotate the cable end around to see the back to see how it is attached. While in its resting position the cable end is pulled towards you to remove.

5. Remove the 3 throttle body mounting bolts (8mm socket).

6. Remove throttle body from intake manifold. The original gasket is reusable and can be left in place.

IAC motor, 4.7L engine

Cleaning the throttle body and IAC plunger

NOTE: Clean the throttle body in a well ventilated area as the fumes from the cleaner can be very strong as well as very flammable. Safety goggles or glasses are a good idea if using a spray cleaner, brushes or compressed air. Read and follow the safety precautions on the container of the cleaner that you are using.

1. With a T-25 torx driver, remove the two screws that attach the IAC motor to the throttle body and carefully remove the motor by pulling it straight out (When looking at the throttle body straight-on, the IAC motor is on your lower right). Carefully clean the IAC motor shaft/plunger with the TB cleaner. Point the shaft downward so that residue will not run into the motor. Do not twist the plunger shaft while cleaning it as damage to the motor may result. Set aside and let dry.

2. Using a shop rag soaked with throttle body or carburetor cleaner, remove any carbon build up from the entire throttle body bore, butterfly plate and IAC shaft. A tootbrush works well to clean the corners around the plate. If using a spray cleaner it can be sprayed into the tight spots around the plate. Q-tips can also be used for cleaning but be sure to not leave any cotton fiber residue in the throttle body. Also clean the entire top and bottom surfaces of the throttle body. If desired you can use a shallow pan to place the throttle body into for cleaning. For stubborn deposits, the cleaner can be left to soak for awhile. Spray throttle body with compressed air to assist in drying.

3. Reinstall the IAC motor to the throttle body. Make sure that its O-ring gasket is properly seated between the body of the IAC motor and the throttle body.

4. Clean the mounting surface and the rubber o-ring gasket on the intake manifold. You can also reach in and clean the frontmost areas inside the intake manifold throttle body opening. Be very careful to not let any loose debri remain inside.

Throttle body installation

A set screw is used to mechanically limit the position of the throttle body throttle plate. Never attempt to adjust the engine idle speed using this screw. All idle speed functions are controlled by the Powertrain Control Module (PCM).

4.0L installation

1. Install new throttle body-to-intake manifold gasket.

2. Install throttle body to intake manifold.

3. Install four mounting bolts. Tighten bolts to 100 in. lbs. (11 N·m) torque.

4. Install control cables.

5. Install electrical connectors.

6. Install air duct and air box at throttle body.

4.7L installation

1. Install throttle body to intake manifold by positioning throttle body to manifold alignment pins.

2. Install three mounting bolts. Tighten bolts to 105 in. lbs. (12 N·m) torque.

3. Install control cables.

4. Install vacuum line hose to throttle body.

5. Install electrical connectors.

6. Install air duct/air box at throttle body.

Finishing up

Start the engine and let it idle for a couple minutes. This will let the PCM re-learn the idle settings. Complete relearning of the settings could take several cold engine startups.

|